How Much Does 2 Squares of Vinyl Siding Cover?

Understanding Vinyl Siding Measurement

How much does 2 square of vinyl siding cover – Accurately calculating the amount of vinyl siding needed for a project is crucial for avoiding material shortages or excessive waste. Understanding the standard measurements and variations in siding profiles is key to successful planning. This section will clarify the typical dimensions of vinyl siding and how these dimensions affect coverage area.Standard Vinyl Siding Dimensions and CoverageA standard vinyl siding square typically covers 100 square feet.

However, this isn’t a fixed dimension like a 10ft x 10ft square. Instead, it represents the area covered by a specific quantity of siding panels, taking into account overlaps and waste. The actual dimensions of individual panels vary depending on the manufacturer and the siding profile.

Vinyl Siding Profile Variations and Coverage, How much does 2 square of vinyl siding cover

Different vinyl siding profiles have varying widths and lengths, directly impacting the square footage covered. For instance, a wider panel will cover more horizontal area than a narrower one, reducing the number of panels required to cover a given wall area.

Similarly, longer panels minimize the number of vertical seams, potentially reducing installation time and improving the aesthetic appeal. The complexity of the profile (e.g., the presence of intricate details or textures) may also slightly affect the effective coverage due to potential waste during cutting and fitting.

Common Vinyl Siding Square Sizes and Coverage Areas

The following table illustrates common vinyl siding square sizes and their corresponding coverage. Note that these are approximate values, and actual coverage may vary slightly depending on the specific product and installation method. Always consult the manufacturer’s specifications for precise coverage information.

| Panel Length (ft) | Panel Width (in) | Approximate Square Feet per Panel | Approximate Number of Panels per Square |

|---|---|---|---|

| 12 | 12 | 12 | 8.33 |

| 10 | 12 | 10 | 10 |

| 8 | 12 | 8 | 12.5 |

| 12 | 6 | 6 | 16.67 |

Calculating Coverage Area

Accurately calculating the square footage of your wall and the number of vinyl siding squares needed is crucial for a successful siding project. Underestimating can lead to material shortages, while overestimating results in unnecessary expenses. This section will guide you through a step-by-step process to ensure you purchase the correct amount of siding.Calculating the total square footage of a wall involves straightforward measurements and calculations.

The process accounts for the wall’s dimensions and factors in potential waste to ensure sufficient material. This calculation is fundamental to determining the number of siding squares required.

Wall Square Footage Calculation

To calculate the square footage of a wall, you need its height and width. Measure the height and width of each wall section separately, if necessary, to account for variations in shape. For instance, a rectangular wall 10 feet high and 20 feet wide has an area of 200 square feet (10 ft x 20 ft = 200 sq ft).

For walls with irregular shapes, break them down into smaller, easily measurable rectangles or triangles and calculate the area of each section before summing them. Remember to convert all measurements to the same unit (feet or meters) before performing calculations.

Calculating the Number of Siding Squares Needed

Once the total square footage of the wall is known, determining the number of siding squares needed is relatively simple. A standard vinyl siding square covers 100 square feet. Therefore, divide the total wall square footage by 100 to find the number of squares.

For example, a 200 square foot wall would require 2 squares of siding (200 sq ft / 100 sq ft/square = 2 squares). However, it is essential to add extra material to account for waste.

Siding Needs Formula with Waste Factor

A practical formula to calculate siding needs, incorporating a waste factor, is:

Total Siding Squares = (Total Wall Square Footage + Waste Percentage) / 100 sq ft/square

The waste percentage accounts for cuts, fitting around windows and doors, and general material loss. A 10% waste factor is a reasonable estimate for most projects, but this can vary depending on the complexity of the wall and your experience.

For example, if you have a 200 square foot wall and use a 10% waste factor:

Total Siding Squares = (200 sq ft + (200 sq ft

0.10)) / 100 sq ft/square = 2.2 squares

Since you can’t buy fractions of a square, you would need to round up to 3 squares.

Factors Influencing Siding Quantity

Several factors influence the total amount of siding required beyond the basic wall area. These include:

- Windows and Doors:These openings reduce the actual siding area needed. Measure the dimensions of each window and door and subtract their areas from the total wall area before calculating the number of siding squares.

- Complex Wall Shapes:Walls with many angles, curves, or unusual features will generally require more siding due to increased cutting and fitting.

- Waste Factor:As mentioned earlier, a higher waste factor should be considered for complex projects or for those with limited experience in siding installation.

- Overlap and Trim:Consider the overlap required between siding pieces and the amount of trim needed around windows, doors, and corners. This will influence the overall amount of siding required.

Waste and Overlap Considerations

Accurate vinyl siding estimation requires accounting for material waste. Several factors contribute to this waste, and understanding these factors allows for more precise material purchasing and minimizes project costs. Proper planning and skilled installation techniques significantly reduce waste, leading to a more efficient and cost-effective project.Waste in vinyl siding installation stems from several sources.

Cutting pieces to fit around windows, doors, and corners inevitably generates scraps. Damaged pieces during handling or unforeseen circumstances like miscuts also contribute. Furthermore, the need for overlapping pieces to ensure watertight seals adds to the overall material consumption.

These factors, along with variations in wall surfaces, impact the final quantity of siding needed.

Sources of Vinyl Siding Waste

Common sources of waste include cuts needed to fit around architectural features like windows and doors, cuts required for fitting around corners and complex angles, and unavoidable scrap pieces resulting from measuring and cutting errors. Damage during transportation, handling, or installation also adds to the waste.

Finally, the necessary overlap of siding pieces to create a weather-resistant barrier contributes to material usage beyond the theoretical square footage of the wall.

Minimizing Waste During Installation

Careful planning and precise measurements are crucial for minimizing waste. Using accurate measurements and creating detailed cutting diagrams before beginning installation helps reduce errors. Employing efficient cutting techniques and using appropriate tools ensures minimal material loss during the cutting process.

Careful handling of the siding prevents damage, and the use of pre-cut components, where applicable, reduces the need for on-site cutting. Furthermore, purchasing slightly more material than initially calculated can account for unexpected waste. For example, adding 5-10% to the total calculated square footage often proves sufficient to accommodate typical waste.

Typical Waste Factors in Siding Projects

A typical waste factor for vinyl siding projects ranges from 5% to 15%. This percentage accounts for the factors mentioned previously, including cuts, overlaps, and potential damage. The exact percentage can vary depending on the complexity of the project.

For example, a simple, rectangular house will likely have a lower waste percentage compared to a house with many complex angles, dormers, or other architectural features. A project with many irregularly shaped areas might even exceed the 15% range.

Tips to Reduce Material Waste

Implementing these strategies can significantly reduce material waste:

- Precisely measure all wall surfaces before purchasing siding.

- Create detailed cutting diagrams to visualize and plan cuts efficiently.

- Use sharp tools and proper cutting techniques to minimize scrap.

- Handle siding carefully to avoid damage during transport and installation.

- Utilize pre-cut components whenever possible.

- Consider using scrap pieces for smaller areas or trim work.

- Purchase extra material, typically 5-15%, to account for unforeseen waste.

- Work with experienced installers who are skilled in minimizing waste.

Types and Costs of Vinyl Siding: How Much Does 2 Square Of Vinyl Siding Cover

Vinyl siding offers a wide range of options, impacting both aesthetics and overall project cost. Understanding the price variations between different grades and styles is crucial for accurate budgeting. Factors such as thickness, color, and texture significantly influence the final cost per square foot.

Vinyl Siding Grades and Styles

Different manufacturers categorize their vinyl siding into grades, often reflecting durability and features. Higher grades generally offer thicker material, enhanced UV resistance, and more realistic textures. Styles range from simple, traditional panels to more complex designs mimicking wood shakes or stone.

Premium options may include insulated siding for improved energy efficiency, further impacting cost.

Cost Variations Based on Features

The thickness of the vinyl siding directly affects its durability and price. Thicker siding is more resistant to damage and warping, justifying a higher cost. Color choices also play a role; certain colors, especially those requiring specialized pigments, may be more expensive.

Similarly, textured siding, designed to replicate the look of wood or stone, often commands a higher price than smooth siding due to the added manufacturing complexity.

Price Ranges for Different Vinyl Siding Options

Price per square varies greatly depending on the factors discussed above. Entry-level vinyl siding might range from $1 to $3 per square foot, while mid-range options could cost $3 to $6 per square foot. Premium siding, including insulated varieties with advanced features, can easily reach $6 to $10 or more per square foot.

These prices are estimates and can fluctuate based on location, supplier, and current market conditions. For example, a homeowner in a rural area might pay slightly more due to transportation costs. Conversely, bulk purchases could lead to lower per-square-foot pricing.

Cost Comparison Table

| Vinyl Siding Type | Thickness (inches) | Texture | Approximate Cost per Square Foot ($) |

|---|---|---|---|

| Economy | 0.040 | Smooth | 1.50

|

| Standard | 0.046 | Smooth or lightly textured | 3.00

|

| Premium | 0.050+ | Woodgrain, stone, or other complex textures | 5.00

|

| Insulated | 0.046+ with insulation | Various | 7.00

|

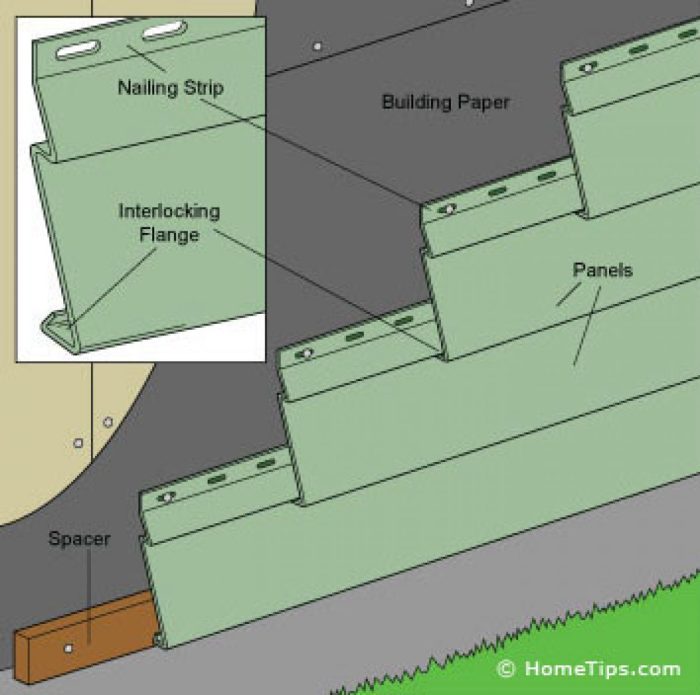

Visual Representation of Coverage

Understanding how two squares of vinyl siding visually appear on a house is crucial for project planning and material estimation. This section provides a detailed description of a typical application, focusing on the visual aspects of installation, including seam placement and overlaps.A typical house section, perhaps a 10ft x 8ft wall, covered with two squares of vinyl siding (assuming standard 100 sq ft per square), would demonstrate a relatively small area of coverage.

This is a common size for a smaller wall section, such as a gable end or a portion of a side wall. The visual impact would depend heavily on the chosen siding color and style.

Siding Installation on a 10ft x 8ft Wall

Consider a plain, light gray vinyl siding applied to a 10ft x 8ft wall. Two squares of siding, totaling 200 square feet, would be sufficient to cover this area, with some material left over, depending on the amount of waste generated during cutting and fitting.

The installation would begin at the bottom, with the first course of siding installed horizontally, overlapping the course below by approximately 1 inch. Each subsequent course would follow, maintaining this consistent overlap. Vertical seams would be visible where individual siding panels butt together, usually running along the wall’s vertical axis.

These seams should be neatly aligned for a clean, professional appearance. Any corners would necessitate using J-channel or other corner trim pieces, which are also vinyl and are designed to neatly finish the edges and allow the siding to wrap around corners cleanly.

The top course would be finished with a final piece of siding, carefully cut to fit and ensuring consistent overlap with the course below. The overall visual effect would be a neat, uniform covering of the wall with subtle horizontal lines created by the siding’s overlaps.

The light gray color would provide a clean, neutral look. Variations in light and shadow would create subtle textural depth across the surface, highlighting the horizontal lines and the slight variation in color caused by the panel overlap. The visual impact would be a simple, clean, and effectively covered wall section.

Final Review

Successfully estimating the amount of vinyl siding needed for your project is crucial for both budget and installation efficiency. By understanding the standard measurements, accounting for waste, and considering the various types and costs of siding, you can confidently plan your project.

Remember to always factor in extra material to account for unforeseen circumstances. With careful planning and the information provided here, you can approach your siding project with confidence and achieve the beautiful, weather-resistant exterior you envision.