Do They Still Make Aluminum Siding?

Current Manufacturers of Aluminum Siding

Do they still make aluminum siding – Aluminum siding remains a popular choice for homeowners due to its durability, low maintenance, and relatively affordable price point. While the market has seen shifts over the years, several manufacturers continue to produce and distribute high-quality aluminum siding across the United States.

Understanding who these manufacturers are and the features of their products is crucial for consumers making informed decisions about their home’s exterior.

Major Aluminum Siding Manufacturers in the United States

Several companies continue to be significant players in the US aluminum siding market. The following table provides a summary of five major manufacturers, their locations, website addresses, and notable features of their siding offerings. It’s important to note that specific product lines and features can change, so it’s always best to check the manufacturer’s website for the most up-to-date information.

| Manufacturer | Location | Website | Notable Features |

|---|---|---|---|

| Alcoa (now part of Arconic) | Pittsburgh, PA (and other locations) | While Alcoa no longer directly markets residential aluminum siding, information on their broader building products can be found through Arconic’s website. (Specific links to residential siding may be limited.) | Historically known for high-quality aluminum products; their legacy continues to influence industry standards. Information on their past siding lines can be found through archival sources and older contractor websites. |

| Mastic Home Exteriors (a division of Ply Gem) | Multiple locations across the US | (Check for current website address; Ply Gem has undergone mergers and acquisitions.) | Offers a wide variety of colors and styles; known for its comprehensive product lines and distribution network. |

| CertainTeed | Valley Forge, PA (and other locations) | (Check their website for current product offerings.) | Provides a range of siding options, often including aluminum siding within their broader exterior cladding portfolio. Focus may be on integrated systems and warranties. |

| Royal Building Products | Multiple locations across the US | (Check their website for current product offerings.) | Offers a variety of exterior cladding solutions, often including aluminum siding. May focus on specific styles or performance characteristics. |

| Other Regional Manufacturers | Various locations across the US | Information will vary greatly. | Numerous smaller manufacturers and distributors exist, often focusing on regional markets or specialized applications. These companies may offer unique styles or finishes. |

Popularity and Market Trends: Do They Still Make Aluminum Siding

Aluminum siding, once a dominant force in the exterior cladding market, has seen its popularity fluctuate over the past few decades. While it still holds a niche, its market share has been steadily eroded by newer materials offering various advantages.

Understanding the current market demand and the factors influencing its trajectory is crucial for homeowners and industry professionals alike.Aluminum siding’s current market demand is significantly lower compared to other materials such as vinyl and fiber cement. This shift reflects evolving homeowner preferences and technological advancements in the siding industry.

Market Share Comparison of Siding Materials

The following hypothetical bar graph illustrates the approximate market share of different siding materials over the last decade. Note that precise figures are difficult to obtain due to the fragmented nature of the market and variations in reporting methodologies.

However, the general trend accurately reflects industry observations.*(Imagine a bar graph here. The X-axis represents the years (2014-2024), and the Y-axis represents market share percentage. The bars would show a gradual decline in aluminum siding’s market share (from perhaps 15% in 2014 to 5% in 2024), a corresponding rise in vinyl siding’s share (from 40% to 60%), and a moderate increase in fiber cement’s share (from 10% to 20%).

Other materials, such as wood and brick, would maintain relatively stable, smaller shares.)*The graph demonstrates a clear trend: a consistent decline in the market share of aluminum siding, accompanied by a substantial increase in the popularity of vinyl siding.

Fiber cement siding also shows growth, indicating a consumer preference for materials perceived as offering superior durability and aesthetic appeal. This shift reflects broader trends in home construction and renovation, where aesthetics and long-term value are increasingly prioritized.

Factors Influencing Aluminum Siding’s Popularity

Several factors contribute to the decline in aluminum siding’s popularity. These include the emergence of more aesthetically pleasing and durable alternatives, such as vinyl and fiber cement, perceived limitations in terms of design flexibility, and concerns about potential dents and scratches.

The relatively high cost of installation and maintenance compared to vinyl siding, especially when considering the total lifecycle cost, also impacts its market appeal.

Cost-Effectiveness of Aluminum Siding

While initially, the upfront cost of aluminum siding might seem competitive, its long-term cost-effectiveness is often debated. Vinyl siding typically boasts a lower initial cost, while fiber cement offers superior longevity and requires less frequent maintenance. Therefore, the total cost of ownership, encompassing initial purchase, installation, maintenance, and lifespan, needs to be carefully considered when comparing these materials.

For example, while aluminum siding might require repainting after a few years, vinyl siding generally needs less maintenance. The higher initial cost of fiber cement is often offset by its much longer lifespan, making it a potentially more cost-effective option in the long run.

Advantages and Disadvantages of Aluminum Siding

Aluminum siding has been a popular choice for home exteriors for decades, offering a balance of aesthetics and practicality. Understanding its advantages and disadvantages is crucial for homeowners considering this option for their homes. This section will detail the benefits and drawbacks to help you make an informed decision.

Durability and Longevity of Aluminum Siding

Aluminum siding is renowned for its durability. Its inherent strength makes it resistant to damage from impacts, such as hail, and it’s less susceptible to cracking or warping than some other materials. This resilience translates to a longer lifespan, contributing to the overall value of the home.

The material’s resistance to rot, insect infestation, and fungal growth further enhances its longevity. Proper installation and regular maintenance are key factors in maximizing its lifespan.

Maintenance Requirements for Aluminum Siding

Aluminum siding requires minimal maintenance compared to other siding materials. A simple periodic cleaning with soap and water is usually sufficient to remove dirt and debris. Unlike wood siding, it doesn’t need painting or staining, saving time and money on upkeep.

This low-maintenance characteristic makes it an attractive option for busy homeowners or those who prefer a less demanding exterior maintenance schedule. However, occasional inspections for damage are still recommended.

Weather Resistance Properties of Aluminum Siding

Aluminum siding excels in withstanding various weather conditions. Its resistance to moisture, extreme temperatures, and strong winds makes it a suitable choice for regions experiencing harsh climates. It won’t rot, warp, or become brittle like some other materials, ensuring consistent performance over time.

This resilience contributes to the long-term structural integrity of the home and reduces the risk of costly repairs due to weather damage.

Susceptibility to Dents and Dings in Aluminum Siding

While durable, aluminum siding is susceptible to dents and dings from impacts. Hard objects, such as falling branches or sports equipment, can leave noticeable marks on the surface. While these imperfections might not compromise the structural integrity of the siding, they can detract from the home’s aesthetic appeal.

Repairing these dents can be challenging and may require professional assistance.

Potential for Fading and Color Degradation in Aluminum Siding

Aluminum siding, especially in darker colors, can fade over time due to prolonged exposure to sunlight and UV rays. This fading can result in an uneven appearance, diminishing the curb appeal of the home. While the fading doesn’t necessarily affect the structural integrity, it can necessitate replacement or repainting if a consistent appearance is desired.

The rate of fading can vary depending on the quality of the paint and the intensity of sunlight in the region.

Lifespan Comparison of Aluminum, Vinyl, and Fiber Cement Siding

The lifespan of aluminum siding generally ranges from 40 to 50 years, depending on the quality of the material, installation, and environmental conditions. Vinyl siding typically lasts between 20 and 30 years, while fiber cement siding boasts a significantly longer lifespan, often exceeding 50 years.

However, the overall cost of installation and potential maintenance needs should be factored into the comparison to determine the most cost-effective option over the long term.

- Advantages of Aluminum Siding:

- High durability and resistance to damage.

- Low maintenance requirements.

- Excellent weather resistance.

- Long lifespan (40-50 years).

- Disadvantages of Aluminum Siding:

- Susceptibility to dents and dings.

- Potential for fading and color degradation.

Installation and Maintenance

Aluminum siding installation and proper maintenance are crucial for ensuring the longevity and aesthetic appeal of your home’s exterior. Understanding the process and necessary upkeep can save you time, money, and potential headaches down the line. This section details the installation process, provides a maintenance guide, and addresses common installation problems.

Aluminum Siding Installation Process

Installing aluminum siding requires careful preparation and the right tools. The process generally involves several key steps, beginning with accurate measurements and proper surface preparation. Tools needed include measuring tapes, levels, saws, shears, drills, and various fasteners. Safety equipment, such as safety glasses and gloves, is also essential.

Step-by-Step Guide to Aluminum Siding Installation

- Preparation:Thoroughly clean the existing wall surface, removing any loose paint, debris, or other obstructions. Repair any damaged areas of the underlying sheathing. Ensure the surface is dry before proceeding.

- Measuring and Cutting:Accurately measure the wall sections to determine the necessary lengths of siding panels. Use appropriate tools to cut the panels to the correct size, ensuring clean, straight cuts.

- Installation of J-Channel and Starter Strip:Install J-channel along the edges and corners of the wall, providing a starting point and finishing edge for the siding. Next, install the starter strip along the bottom edge of the wall.

- Panel Installation:Begin installing the siding panels, starting from the bottom and working upwards. Overlap each panel slightly, ensuring proper alignment and secure fastening. Use appropriate fasteners for your siding type and wall material.

- Finishing:Install any remaining trim pieces, such as corner trim, J-channel, and fascia, to complete the installation. Ensure all seams are tightly sealed to prevent water penetration.

Aluminum Siding Maintenance

Regular maintenance significantly extends the lifespan of aluminum siding. A simple annual inspection and cleaning can prevent minor issues from becoming major problems. This includes checking for loose panels, damaged areas, and signs of corrosion.

Step-by-Step Guide to Aluminum Siding Maintenance

- Annual Inspection:Inspect the siding for any loose panels, dents, scratches, or signs of corrosion. Pay close attention to seams and corners where water damage is most likely to occur.

- Cleaning:Clean the siding using a mild detergent and water solution. Use a soft-bristled brush or sponge to avoid scratching the surface. Rinse thoroughly with clean water.

- Repairing Minor Damage:Small dents or scratches can often be repaired using a putty or filler designed for aluminum. Larger damage may require panel replacement.

- Caulk Repair:Inspect and replace any damaged caulking around windows, doors, and other openings to prevent water infiltration.

- Painting (If Necessary):Aluminum siding can be painted to refresh its appearance. Use a high-quality exterior paint designed for aluminum surfaces.

Common Installation Issues and Solutions

Several issues can arise during aluminum siding installation. For instance, improper measurement can lead to gaps or misaligned panels. Using incorrect fasteners may result in loose panels or damage to the siding. Water penetration can occur due to insufficient caulking or damaged flashing.

Solutions involve careful re-measurement, using appropriate fasteners, and ensuring proper sealing.

Flowchart Illustrating Aluminum Siding Installation

The flowchart would begin with a “Start” node. This would branch to “Site Preparation,” which includes cleaning and surface repairs. The next step, “Measurement and Cutting,” would follow, leading to “Installation of J-Channel and Starter Strip.” This would then connect to “Panel Installation,” which involves installing panels from bottom to top, ensuring proper overlap and fastening.

Finally, “Finishing and Inspection” would complete the process, leading to an “End” node. Each step would have decision points to address potential problems, such as needing additional materials or repairs, before moving to the next stage. The flowchart visually represents the sequential nature of the installation process, highlighting the dependencies between each step.

Environmental Impact

Aluminum siding, while durable and long-lasting, carries environmental implications throughout its lifecycle, from manufacturing to disposal. Understanding these impacts allows for informed decisions regarding its use and responsible management. This section will examine the environmental footprint of aluminum siding production, its comparative impact against other materials, and available recycling options.Aluminum siding’s environmental impact is primarily associated with the energy-intensive process of aluminum production from bauxite ore.

This process involves significant energy consumption, leading to greenhouse gas emissions. Furthermore, the manufacturing process generates waste, although advancements in recycling have reduced this impact considerably. Disposal also presents an environmental challenge, although aluminum’s recyclability offers a significant mitigation strategy.

Aluminum Production and Greenhouse Gas Emissions

The extraction and refining of bauxite ore, the primary source of aluminum, requires substantial energy, predominantly from fossil fuels. This results in significant carbon dioxide (CO2) emissions contributing to climate change. While advancements in hydroelectric power and other renewable energy sources are being incorporated into the aluminum production process, the overall energy intensity remains a considerable environmental factor.

For instance, studies have shown that the carbon footprint of aluminum production can vary significantly depending on the energy sources utilized and the efficiency of the refining process. A shift towards renewable energy sources in aluminum smelting plants is crucial for reducing this impact.

Comparison with Other Siding Materials

Aluminum siding’s environmental impact must be considered in relation to other common siding materials such as vinyl, wood, and fiber cement. Vinyl siding, derived from petroleum, has a high carbon footprint associated with its production and limited recyclability. Wood siding, while renewable, can have a significant environmental impact depending on the sourcing and transportation of the lumber, as well as potential deforestation concerns.

Fiber cement siding, a composite material, has a relatively lower carbon footprint compared to vinyl but involves manufacturing processes that produce waste. A comprehensive life-cycle assessment (LCA) is needed to accurately compare the total environmental impact of each material, taking into account manufacturing, transportation, usage, and disposal phases.

Aluminum Siding Recycling

Aluminum is highly recyclable, making it a more sustainable option compared to many other siding materials. The recycling process requires significantly less energy than primary aluminum production, substantially reducing greenhouse gas emissions. Many scrap metal yards and recycling centers accept aluminum siding, and some manufacturers even have take-back programs for their products.

However, the recycling rate for aluminum siding remains relatively low compared to other aluminum products, such as cans. Increased public awareness and improved recycling infrastructure are necessary to improve the recycling rate and minimize the environmental impact of discarded aluminum siding.

Environmental Impact Comparison Table, Do they still make aluminum siding

| Siding Material | Manufacturing | Usage | Disposal |

|---|---|---|---|

| Aluminum | High energy consumption, greenhouse gas emissions | Durable, long lifespan, low maintenance | Recyclable, but low recycling rates |

| Vinyl | High carbon footprint from petroleum-based production | Durable, low maintenance | Limited recyclability, landfill disposal |

| Wood | Variable depending on sourcing and transportation | Renewable, aesthetically pleasing | Biodegradable, but potential for landfill disposal if not properly managed |

| Fiber Cement | Moderate carbon footprint, waste generation | Durable, fire-resistant, low maintenance | Landfill disposal, but some components may be recyclable |

Cost Considerations

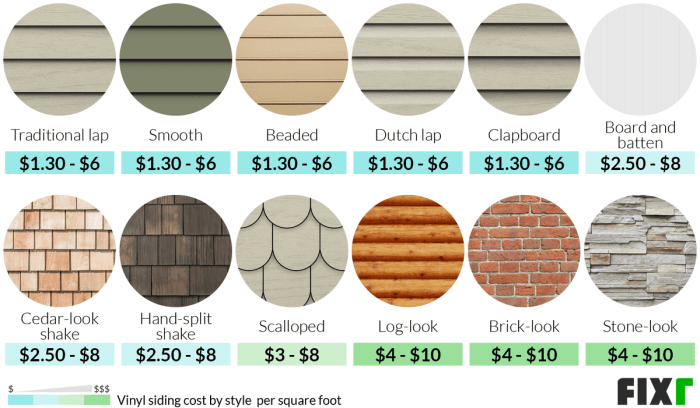

The overall cost of aluminum siding is influenced by a complex interplay of factors, primarily material costs, labor expenses, and the intricacies of installation. Understanding these components is crucial for homeowners planning a siding project, as the final price can vary significantly depending on the chosen materials and the scope of the job.The price of aluminum siding itself is determined by several key elements.

The gauge of the aluminum (thicker gauges are more durable but more expensive), the type of finish (e.g., painted, textured, or with a wood-grain effect), and the presence of additional features (like insulation backing) all impact the cost per square foot.

Higher-quality materials, such as those with superior paint systems offering enhanced longevity and fade resistance, command a higher price. Furthermore, the complexity of the project—a simple, rectangular house will be less expensive to side than one with many angles, dormers, or intricate architectural details—significantly influences labor costs.

Material Costs

Aluminum siding costs typically range from $2 to $8 per square foot, excluding installation. Lower-end options, often with thinner gauges and simpler finishes, fall within the lower range. Premium options, featuring thicker aluminum, sophisticated finishes, and enhanced durability, can reach the higher end of this spectrum.

These price differences reflect the variation in material quality and longevity. For example, a basic painted aluminum siding might cost around $2-$4 per square foot, while a higher-end, textured, insulated siding could cost $6-$8 or more. These prices are estimates and can fluctuate based on market conditions and supplier pricing.

Labor Costs

Labor costs constitute a significant portion of the total project expense. The hourly rate for skilled siding installers varies geographically and seasonally. The complexity of the installation, influenced by the house’s design and existing siding conditions, also plays a role.

Removing old siding, preparing the underlying surface, and addressing any necessary repairs can add considerable time and cost to the project. Expect to pay anywhere from $3 to $10 or more per square foot for labor, depending on these factors.

A simple installation on a straightforward house might fall at the lower end, while a complex project on a multi-story home with intricate details could easily reach the higher end.

Long-Term Cost-Effectiveness

Aluminum siding, when properly installed and maintained, offers a relatively long lifespan, often lasting 30 to 50 years or more. This longevity contributes to its long-term cost-effectiveness. Compared to other siding options, such as vinyl or wood, aluminum offers a balance between initial cost and long-term maintenance requirements.

While the initial cost of aluminum siding might be higher than vinyl, its durability and lower maintenance needs can result in significant cost savings over the decades. Wood siding, though aesthetically pleasing, demands considerable upkeep, including regular painting or staining, which adds substantial costs over time.

A proper cost analysis should factor in these long-term maintenance expenses to determine the true overall cost of each siding option.

Epilogue

In conclusion, the question “Do they still make aluminum siding?” is answered with a resounding yes. While its market share may have fluctuated, aluminum siding remains a durable, low-maintenance option with a place in the current construction market. Its advantages in weather resistance and longevity, coupled with ongoing advancements in manufacturing and recycling, ensure its continued relevance.

Ultimately, the suitability of aluminum siding depends on individual project needs, budget, and aesthetic preferences. By carefully weighing the pros and cons, homeowners and builders can determine if aluminum siding is the right choice for their specific requirements.