Aluminum Lap Siding Panels: A Comprehensive Guide

Product Overview

Aluminum lap siding panels offer a durable and aesthetically pleasing exterior cladding option for residential and commercial buildings. Their popularity stems from a combination of longevity, low maintenance, and a variety of customizable finishes. This section details the manufacturing process, available finishes, lifespan comparisons, and price points associated with aluminum lap siding.

Aluminum Lap Siding Panel Manufacturing

The manufacturing process begins with aluminum coils, typically made from alloys chosen for their strength and corrosion resistance. These coils are fed into a roll-forming machine, where they are precisely shaped into the characteristic overlapping lap profile. The process involves a series of rollers that bend, shape, and cut the aluminum to the desired dimensions and profile.

Once formed, the panels undergo a cleaning process to remove any impurities or imperfections. Then, they receive their chosen finish, which can involve painting, powder coating, or anodizing. Finally, the finished panels are inspected for quality and packaged for distribution.

Finishes for Aluminum Lap Siding Panels

A wide array of finishes are available to match diverse architectural styles and personal preferences. These finishes enhance the aesthetic appeal and protect the aluminum from the elements. Common finish types include:* Painted Finishes:These offer a broad spectrum of colors and textures, allowing for a high degree of customization.

The paint is typically applied using a high-quality, durable coating designed to withstand UV exposure and fading.

Powder-Coated Finishes

Powder coating provides an exceptionally durable and chip-resistant finish. It’s known for its superior resistance to scratches and weathering compared to paint.

Anodized Finishes

Anodizing is an electrochemical process that creates a protective oxide layer on the aluminum surface. This process enhances the aluminum’s natural resistance to corrosion and provides a long-lasting, low-maintenance finish. Anodized finishes often have a more subtle, metallic appearance.

Lifespan and Durability Compared to Other Siding Materials

Aluminum lap siding boasts a significantly longer lifespan than many other siding materials. While the exact lifespan depends on factors like climate and maintenance, aluminum siding can easily last 50 years or more with minimal upkeep. This contrasts sharply with wood siding, which may require repainting or replacing every 10-15 years, and is susceptible to rot, insect infestation, and moisture damage.

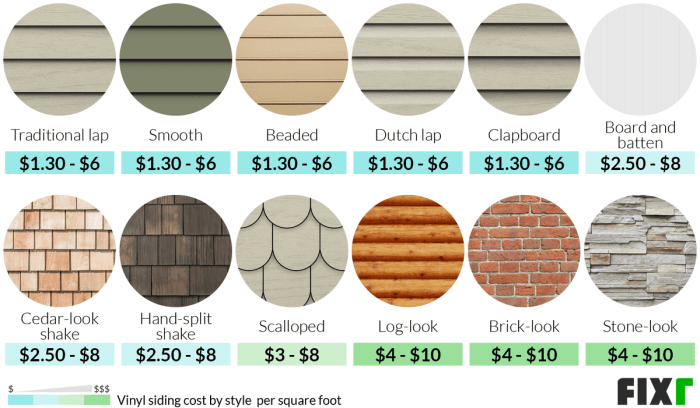

Vinyl siding, while more durable than wood, is still less resistant to impact damage and can become brittle and fade over time, typically lasting 20-30 years. Aluminum offers superior durability and longevity, requiring less maintenance and replacement over its extended service life.

Price Points of Aluminum Lap Siding Panels

The cost of aluminum lap siding varies based on several factors including the chosen finish, panel thickness, and installation complexity. The following table provides a general price range, keeping in mind that actual costs may vary depending on location and contractor:

| Siding Type | Panel Cost (per sq ft) | Installation Cost (per sq ft) | Total Estimated Cost (per sq ft) |

|---|---|---|---|

| Painted Aluminum | $2.50

|

$3.00

|

$5.50

|

| Powder-Coated Aluminum | $3.50

|

$3.00

|

$6.50

|

| Anodized Aluminum | $4.50

|

$3.00

|

$7.50

|

| Vinyl Siding | $1.00

|

$2.00

|

$3.00

|

*Note: These are estimates and actual costs can vary significantly based on location, project specifics, and contractor.*

Installation and Maintenance: Aluminum Lap Siding Panels

Aluminum lap siding offers a durable and attractive exterior cladding solution. Proper installation and regular maintenance are crucial for maximizing its lifespan and aesthetic appeal. This section details the installation process, addresses common challenges, and provides a comprehensive maintenance schedule.

Step-by-Step Installation Guide

Successful aluminum lap siding installation requires careful planning and execution. The following steps Artikel a typical process, though specific details may vary depending on the chosen product and site conditions. Always consult the manufacturer’s instructions for your specific siding.

- Preparation:Begin by ensuring a solid and level surface. Repair any damaged sheathing or underlying structure. Measure and mark the area for siding placement, accounting for overlaps and cuts.

- Installation of Starter Strip:Install the starter strip along the bottom edge of the wall, ensuring it’s level and plumb. This provides a consistent base for the siding panels.

- Panel Installation:Install the first course of siding panels, overlapping them according to the manufacturer’s specifications. Use appropriate fasteners, ensuring they are driven straight to avoid damage.

- J-Channel Installation:Install J-channel around windows and doors, ensuring proper sealing to prevent water infiltration. This provides a neat finish and protects these vulnerable areas.

- Corner Installation:Use corner trim to neatly finish exterior corners. Ensure proper overlap and secure fastening.

- Finishing:Install the final course of siding panels, trimming as needed to achieve a clean, finished look. Inspect the entire installation for proper alignment and secure fastening.

Common Installation Issues and Solutions

Several challenges can arise during aluminum lap siding installation. Addressing these proactively ensures a successful project.

- Uneven Surfaces:Uneven walls can lead to misaligned siding and compromised aesthetics. Addressing underlying structural issues before installation is crucial. Solutions include shimming or using furring strips to create a level surface.

- Improper Fastening:Using incorrect fasteners or driving them too deeply or shallowly can damage the siding or compromise its structural integrity. Using the correct fasteners and following manufacturer guidelines is essential.

- Water Infiltration:Improper sealing around windows, doors, and corners can lead to water damage. Careful sealing with appropriate caulk and flashing is critical. Properly installed J-channel and corner trim are essential.

Aluminum Siding Maintenance and Cleaning

Regular cleaning and maintenance extend the life and beauty of aluminum lap siding.

Aluminum siding is relatively low-maintenance. Regular cleaning with a garden hose and a soft-bristled brush is usually sufficient to remove dirt and debris. For tougher stains, a mild detergent solution can be used. Avoid abrasive cleaners or harsh chemicals, as these can damage the siding’s finish.

Always rinse thoroughly after cleaning.

Preventative Maintenance Schedule

A regular maintenance schedule helps prevent costly repairs.

| Task | Frequency | Details |

|---|---|---|

| Cleaning | Annually (or as needed) | Wash with water and a soft brush; use mild detergent for stubborn stains. |

| Inspection | Semi-annually | Check for loose panels, damaged areas, or signs of water infiltration. |

| Caulk Repair | As needed | Inspect and repair any damaged caulking around windows, doors, and other penetrations. |

| Fastener Check | Every 2-3 years | Inspect fasteners for tightness and replace any that are loose or damaged. |

Design and Aesthetics

Aluminum lap siding offers a remarkable blend of durability and aesthetic appeal, providing homeowners with a wide array of design possibilities to enhance the curb appeal of their homes. The versatility of aluminum siding allows for seamless integration with various architectural styles, transforming the exterior into a reflection of personal taste and style.Aluminum lap siding panels present a diverse palette of color options and styles, catering to a broad spectrum of preferences.

The inherent properties of the material allow for consistent color retention and resistance to fading, ensuring long-lasting beauty. This section will explore the various design aspects of aluminum lap siding, empowering homeowners to make informed choices for their projects.

Color Options and Styles

Aluminum lap siding is available in a vast array of colors, ranging from classic earth tones to bold, contemporary hues. These colors are typically achieved through a durable powder-coating process, providing excellent protection against the elements and ensuring the color remains vibrant for years.

Styles vary from traditional smooth finishes to those that mimic the texture of wood grain, offering a wide range of visual choices to match any architectural style. Popular color choices include various shades of gray, beige, brown, and white, but many manufacturers offer custom color matching options to perfectly complement a home’s existing design scheme.

Complementing Architectural Styles

Aluminum lap siding’s adaptability allows it to complement a variety of architectural styles. For instance, a traditional colonial home might be beautifully accented with a classic white or muted gray aluminum lap siding, emphasizing the home’s timeless elegance. Conversely, a modern farmhouse style could be enhanced with a bolder color choice, such as a deep charcoal gray or a warm, earthy brown, reflecting the rustic charm of the architectural style.

The clean lines and even texture of aluminum siding can also beautifully complement contemporary architectural styles, creating a sleek and sophisticated look. The versatility of the material allows for customization, ensuring it can harmoniously integrate into various designs.

Choosing Panel Size and Profile

Selecting the appropriate panel size and profile is crucial for achieving the desired aesthetic outcome. Larger panels create a cleaner, more modern look with fewer visible seams, while smaller panels can add visual texture and interest. The profile, referring to the shape and depth of the panel, also influences the overall appearance.

A deeper profile creates a more pronounced shadow line, enhancing the three-dimensional effect, while a shallower profile offers a smoother, more understated look. Considerations should also include the size and scale of the house; larger homes may benefit from larger panels, while smaller homes may be better suited to smaller panels to avoid overwhelming the structure.

Examples of Siding Designs

The versatility of aluminum lap siding is showcased in its application across diverse architectural designs.

- A Victorian-style home might utilize smaller panels with a deeper profile and a dark, contrasting color to highlight the intricate detailing of the architecture.

- A contemporary ranch-style house could feature large, smooth panels in a light neutral color, emphasizing the clean lines of the design.

- A craftsman-style bungalow might use medium-sized panels with a wood-grain finish in a warm brown tone, complementing the natural aesthetic.

- A modern minimalist home could use extra-large panels in a single, bold color, creating a dramatic and impactful statement.

Environmental Impact and Sustainability

Aluminum lap siding offers a compelling combination of durability and environmental responsibility, making it a sustainable choice for homeowners concerned about the ecological footprint of their building materials. Its inherent properties contribute to a lower overall environmental impact compared to some alternatives, and its recyclability further enhances its sustainability profile.Aluminum’s environmental benefits stem from its inherent properties and lifecycle.

The material is highly durable, requiring less frequent replacement than other siding options, thus reducing the need for resource extraction and manufacturing over time. Furthermore, its resistance to rot, insect damage, and fire minimizes the need for chemical treatments and reduces the risk of premature failure.

Recyclability and Sustainability of Aluminum Siding

Aluminum is infinitely recyclable without loss of quality. This means that aluminum siding can be melted down and reused to create new aluminum products repeatedly. The energy required to recycle aluminum is significantly less than that needed to produce it from raw bauxite ore, resulting in considerable energy savings and reduced greenhouse gas emissions.

The high recyclability rate of aluminum contributes significantly to its overall sustainability profile, reducing the demand for virgin materials and minimizing waste in landfills. Many municipalities offer aluminum recycling programs, making responsible disposal straightforward.

Carbon Footprint Comparison with Other Siding Materials

While the exact carbon footprint of aluminum siding varies depending on manufacturing processes and transportation distances, studies generally indicate that it performs competitively compared to other common siding materials. For example, while wood siding might seem like a natural choice, the energy used in logging, transportation, and processing, along with potential deforestation concerns, can significantly impact its overall carbon footprint.

Vinyl siding, although readily available, is a petroleum-based product with a high carbon footprint during manufacturing and disposal. A life-cycle assessment comparing aluminum to wood and vinyl would reveal that aluminum’s durability and recyclability often lead to a smaller overall environmental impact over the lifespan of the siding.

However, it’s crucial to note that comprehensive life-cycle assessments, accounting for all stages of production, use, and disposal, are necessary for accurate comparisons.

Responsible Disposal of Aluminum Siding

Proper disposal of aluminum siding is crucial to maximize its environmental benefits. Instead of sending it to a landfill, homeowners should strive to recycle it. Many scrap metal yards and recycling centers accept aluminum siding. Check with your local waste management authority to identify appropriate recycling facilities in your area.

Before disposal, remove any fasteners or other non-aluminum components to ensure the purity of the recycled material. Properly disposing of aluminum siding prevents the accumulation of waste in landfills and conserves natural resources. Furthermore, some manufacturers may have take-back programs for their aluminum siding products, facilitating responsible recycling and minimizing environmental impact.

Cost Analysis and Value Proposition

Choosing exterior siding is a significant investment, and understanding the long-term cost-effectiveness is crucial. Aluminum lap siding offers a compelling value proposition when compared to other materials, balancing initial cost with longevity and minimal maintenance requirements. This section details the various cost components associated with aluminum siding and demonstrates its return on investment over time.Aluminum lap siding’s initial cost may be higher than some alternatives like vinyl or wood, but its superior durability translates to significant long-term savings.

The reduced need for repairs, repainting, and replacements ultimately makes it a more cost-effective choice over the lifespan of your home.

Long-Term Cost-Effectiveness Compared to Other Options

Aluminum siding stands out for its resilience against the elements. Unlike wood, it doesn’t rot, warp, or require frequent repainting. Compared to vinyl, aluminum offers superior impact resistance and is less prone to damage from hail or strong winds. This translates to lower maintenance costs and fewer unexpected repairs over the decades.

A well-maintained aluminum siding system can easily last 50 years or more, significantly exceeding the lifespan of many competing materials.

Return on Investment (ROI) of Aluminum Siding

The ROI of aluminum siding is realized through reduced maintenance and repair expenses, increased property value, and extended lifespan. While the upfront cost is higher, the savings accrued over the years significantly outweigh the initial investment. For instance, consider a homeowner who avoids the cost of repainting every 5-7 years, a common expense with wood siding.

Over 30 years, these savings can easily amount to several thousand dollars. Furthermore, aluminum siding’s durability can increase the resale value of a property compared to homes with siding requiring frequent maintenance and replacement.

Factors Influencing the Overall Cost of Aluminum Siding Projects

Several factors contribute to the overall cost of an aluminum siding project. These include:

- The size of the house:Larger homes naturally require more materials and labor, increasing the overall cost.

- Complexity of the installation:Homes with intricate architectural details or multiple gables may require more time and expertise, leading to higher labor costs.

- Material choices:Different aluminum siding profiles, colors, and finishes vary in price. Premium finishes and custom colors often command a higher cost.

- Labor costs:Regional variations in labor rates significantly impact the overall project cost. Highly skilled installers in high-demand areas may charge more.

- Permits and inspections:Obtaining necessary permits and scheduling inspections adds to the total project expense.

Cost Components of a Typical Aluminum Siding Installation

The following table Artikels the various cost components of a typical aluminum siding installation for a medium-sized home (approximately 2,000 square feet):

| Cost Component | Estimated Cost Range | Percentage of Total Cost (Estimate) | Notes |

|---|---|---|---|

| Materials (Siding, Trim, Fasteners) | $6,000

|

30-40% | Varies based on material choices and house size. |

| Labor | $8,000

|

40-50% | Dependent on labor rates and project complexity. |

| Preparation and Removal of Old Siding (if applicable) | $1,000

|

5-15% | This cost is only incurred if replacing existing siding. |

| Permits and Inspections | $500

|

2-5% | Varies based on local regulations. |

Note: These cost estimates are approximate and can vary significantly based on location, project specifics, and contractor choices. It’s crucial to obtain multiple bids from reputable contractors to accurately determine the cost for your specific project.

Technical Specifications and Properties

Aluminum lap siding panels offer a compelling combination of durability, aesthetics, and longevity, making them a popular choice for exterior cladding. Understanding their technical specifications and properties is crucial for architects, builders, and homeowners alike to make informed decisions regarding material selection and application.

This section details the key physical characteristics and performance attributes of these panels.

Aluminum Alloy Composition and Properties

Aluminum lap siding panels are typically manufactured from a variety of aluminum alloys, each possessing unique properties that influence the panel’s overall performance. The choice of alloy depends on factors such as desired strength, corrosion resistance, and cost. Common alloys include 3003, 5005, and 6061.

Alloy 3003 offers good workability and corrosion resistance, making it suitable for general-purpose applications. Alloy 5005 provides enhanced strength and corrosion resistance, ideal for demanding environments. Alloy 6061 boasts high strength and excellent weldability, often preferred for complex designs.

The specific properties of each alloy, including tensile strength, yield strength, and elongation, are readily available from manufacturers’ datasheets. These datasheets also typically provide information on the alloy’s chemical composition and recommended fabrication methods.

Physical Dimensions and Weight

Aluminum lap siding panels are available in a range of thicknesses, typically ranging from 0.032 inches to 0.050 inches (0.8mm to 1.3mm). The panel width and length vary depending on manufacturer and design preferences. The weight per square foot is directly related to the thickness and alloy used.

Thicker panels, and those made from higher-strength alloys, will naturally weigh more. For example, a panel made from 0.040-inch thick 5005 alloy will have a different weight per square foot than a panel made from 0.032-inch thick 3003 alloy.

Accurate weight information is essential for structural calculations and transportation planning. This data is typically found in product specifications provided by manufacturers.

Fire Resistance and Weather Resistance, Aluminum lap siding panels

Aluminum’s inherent properties contribute significantly to its fire resistance. It does not readily support combustion and has a high melting point, significantly reducing the risk of fire spread. Aluminum siding panels are often given a Class A fire rating, representing the highest level of fire resistance in building codes.

In terms of weather resistance, aluminum exhibits exceptional durability against corrosion, weathering, and UV degradation. Properly coated aluminum siding panels can withstand harsh weather conditions, including rain, snow, and extreme temperatures, for decades without significant deterioration. The specific coating type and thickness significantly impact the panel’s long-term weather resistance.

For example, Kynar 500® coatings are known for their exceptional UV resistance and color retention.

Thermal Conductivity and Insulation Properties

Aluminum possesses high thermal conductivity, meaning it readily transfers heat. However, this is not necessarily a drawback for siding applications. While aluminum itself does not provide significant insulation, its thin profile minimizes the overall impact on the building’s thermal performance.

The actual thermal performance of an aluminum siding system depends heavily on the underlying insulation and the overall building envelope design. Effective insulation behind the siding is crucial to maintain comfortable indoor temperatures and energy efficiency. The thermal bridging effect of aluminum can be mitigated through proper installation techniques and the use of appropriate insulation materials.

Visual Representation

Imagine a charming two-story colonial-style home nestled on a gently sloping lawn, bordered by mature oak trees and vibrant hydrangeas. The freshly installed aluminum lap siding, in a sophisticated “charcoal gray” hue, complements the home’s architectural details and the surrounding landscape beautifully.

The siding’s subtle texture and even color create a clean, modern look that enhances the home’s curb appeal. The overall aesthetic is one of refined elegance and timeless appeal.This scene showcases the versatility of aluminum lap siding. The charcoal gray color is both neutral and striking, allowing the home’s architectural features – the white trim, the gabled roof, and the charming bay window – to stand out.

The contrast between the dark siding and the lighter elements adds depth and visual interest. The surrounding landscape, with its carefully manicured lawn and lush greenery, further complements the home’s new siding, creating a harmonious and inviting atmosphere.

Close-up View of Aluminum Lap Siding

A close-up examination reveals the subtle texture of the aluminum lap siding panels. The finish is a matte, slightly textured surface, providing a pleasing visual effect that minimizes glare. Individual panels are neatly interlocked, creating a seamless and visually appealing surface with minimal visible seams.

The shadowing effect between the overlapping panels adds depth and dimension to the siding, enhancing its overall aesthetic appeal. Light reflection is soft and even, avoiding harsh glare and creating a consistent and pleasing visual effect across the entire surface.

The subtle variations in light and shadow subtly highlight the horizontal lines of the siding, drawing the eye across the facade of the house. The color consistency is remarkable, with no visible color variation between panels, indicating high-quality manufacturing and installation.

Last Word

Ultimately, aluminum lap siding panels present a compelling option for homeowners and builders seeking a balance of durability, aesthetics, and long-term value. Their resistance to weather damage, low maintenance requirements, and diverse design possibilities make them a strong contender in the siding market.

By carefully considering factors such as cost, installation, and desired aesthetic, you can confidently choose aluminum lap siding panels to enhance the beauty and longevity of your property.