Siding Comparable to Hardie Board: A Comprehensive Guide

Material Composition and Properties: Siding Comparable To Hardie Board

Siding comparable to hardie board – Hardie Board, and its competitors, offer a range of durable siding options, each with distinct material compositions and resulting properties. Understanding these differences is crucial for selecting the best siding for a specific project, considering factors such as budget, desired lifespan, and maintenance preferences.

This section will delve into the composition and manufacturing processes of various fiber cement sidings and compare their performance characteristics.

Fiber Cement Composition and Manufacturing Processes

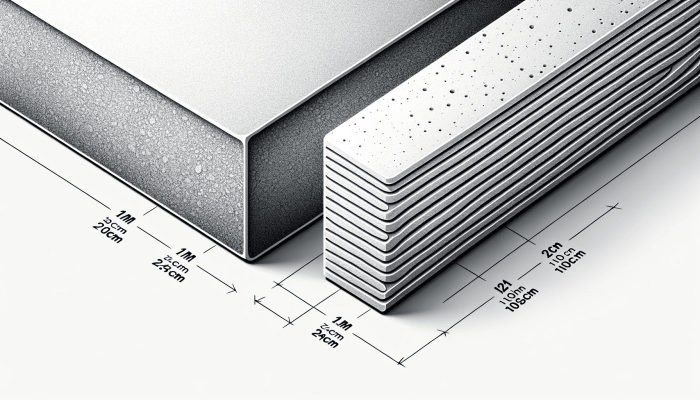

Hardie Board, a leading brand of fiber cement siding, is primarily composed of Portland cement, cellulose fibers, and silica sand. These ingredients are blended, mixed with water, and formed into sheets under high pressure. The sheets are then cured in a high-temperature environment to achieve the desired strength and durability.

This process results in a dense, non-combustible material resistant to moisture, insects, and rot. Other fiber cement siding manufacturers may use slightly different formulations, potentially incorporating other reinforcing fibers or additives, but the core principle remains the same: a composite material leveraging the strength of cement and the reinforcing properties of fibers.

Vinyl siding, in contrast, is primarily made from polyvinyl chloride (PVC), a thermoplastic polymer. It is manufactured through an extrusion process, where molten PVC is forced through a die to create the desired profile. Wood siding, naturally, is derived from trees and undergoes various treatments to enhance its durability, such as pressure-treating with preservatives.

Metal sidings, such as aluminum or steel, are manufactured through processes involving rolling and forming metal sheets into the desired shapes.

Comparative Properties of Siding Materials

The following table summarizes the key properties of Hardie Board compared to vinyl, wood, and aluminum siding. Note that these values can vary depending on the specific product and manufacturer.

| Property | Hardie Board | Vinyl Siding | Wood Siding | Aluminum Siding |

|---|---|---|---|---|

| Weight (lbs/sq ft) | 3-4 | 0.5-1 | 2-4 (depending on wood type) | 0.5-1 |

| Strength (Impact Resistance) | High | Medium-Low | Medium (varies greatly by wood type) | High |

| Durability (Lifespan) | 50+ years | 20-30 years | 15-30 years (depending on wood type and maintenance) | 50+ years |

Impact of Material Composition on Lifespan and Maintenance

The material composition directly influences the lifespan and maintenance requirements of each siding type. Hardie Board’s cement-fiber composition provides inherent resistance to moisture, insects, and fire, contributing to its long lifespan and low maintenance needs. Regular cleaning is typically sufficient.

Vinyl siding, being less durable, is more susceptible to damage from impact and extreme weather conditions. It may require more frequent cleaning and occasional repairs. Wood siding, while aesthetically pleasing, is prone to rot, insect infestation, and fading if not properly treated and maintained.

Regular painting or staining is necessary to extend its lifespan. Aluminum siding, like Hardie Board, boasts a long lifespan and requires minimal maintenance, primarily involving occasional cleaning. However, it can dent more easily than fiber cement. The choice of siding should consider these factors and balance aesthetic preferences with long-term cost and maintenance implications.

Installation Methods and Techniques

Proper installation is crucial for ensuring the longevity and performance of any siding, including Hardie Board and its comparable alternatives. This section details the steps involved in installing Hardie Board siding, highlighting key differences and best practices applicable to various siding materials.

Understanding these techniques will lead to a superior, long-lasting finish.

Hardie Board Siding Installation: A Step-by-Step Guide

The installation process for Hardie Board generally involves these steps: Preparation of the substrate, installation of starter strips, installation of siding panels, and finishing details. While specific steps might vary slightly based on the chosen Hardie Board product and building design, the core principles remain consistent.

- Substrate Preparation:Begin by ensuring a clean, dry, and level substrate. Repair any damaged areas of sheathing and ensure proper ventilation. This is equally crucial for all siding types; neglecting this step can lead to problems regardless of the material chosen.

- Starter Strip Installation:Install a starter strip at the bottom of the wall, providing a consistent starting point for the siding panels. This strip also helps to maintain a straight line and even spacing. Alternative siding types may use similar starting mechanisms, though the specific profiles might differ.

- Siding Panel Installation:Install the siding panels, overlapping them according to manufacturer’s specifications. Ensure proper alignment and spacing between panels. Use appropriate fasteners and avoid overdriving nails to prevent damage. This step necessitates careful attention to detail, irrespective of the siding material used.

- Caulking and Finishing:Caulk all seams and joints to prevent water penetration. Install trim and accessories as needed to complete the installation. Proper caulking is vital for all siding types to ensure water resistance and prevent damage from moisture.

Best Practices for Cutting, Fastening, and Sealing Various Siding Types

Proper cutting, fastening, and sealing techniques are critical for achieving a professional-looking and long-lasting finish. These practices are essential regardless of the siding material used.

- Cutting:Use a sharp blade, whether it’s a circular saw with a fine-tooth blade for Hardie Board or a utility knife for vinyl siding, to ensure clean cuts and prevent chipping or cracking. Pre-drilling pilot holes is recommended for all types of siding, especially for harder materials like fiber cement.

- Fastening:Use galvanized nails or screws appropriate for the siding material. Fasteners should be driven straight to avoid damage and ensure proper holding power. Overdriving can cause cracking, while underdriving can lead to loose panels. Appropriate fastener spacing is critical for all siding types.

- Sealing:Use high-quality, paintable caulk to seal all seams and joints. Ensure complete coverage to prevent water penetration. Choose a caulk that is compatible with the siding material. This is a crucial step for moisture protection, irrespective of the siding chosen.

Tools and Equipment Comparison

The tools required for Hardie Board installation are largely similar to those needed for other siding materials, with some variations based on the material’s properties.

| Tool/Equipment | Hardie Board | Vinyl Siding | Wood Siding |

|---|---|---|---|

| Measuring Tape | ✓ | ✓ | ✓ |

| Circular Saw (with fine-tooth blade) | ✓ | (Utility knife often sufficient) | ✓ |

| Safety Glasses | ✓ | ✓ | ✓ |

| Gloves | ✓ | ✓ | ✓ |

| Nail Gun (or hammer) | ✓ | ✓ | ✓ |

| Caulk Gun | ✓ | ✓ | ✓ |

| Level | ✓ | ✓ | ✓ |

Aesthetic Considerations and Design Options

Choosing siding for your home involves more than just functionality; aesthetics play a crucial role in creating curb appeal and enhancing the overall architectural style. Hardie Board and comparable fiber cement sidings offer a wide range of options to achieve diverse design goals, from classic to contemporary.

This section explores the aesthetic considerations and design choices available.

Siding Styles and Colors

The visual appeal of fiber cement siding is significantly impacted by its style and color. Imagine a home clad in classic clapboard siding, painted a warm, inviting shade of Nantucket gray. The horizontal lines create a sense of traditional elegance.

Now, picture the same house with board and batten siding, painted a deep, rich navy blue. The vertical lines create a different visual rhythm, suggesting a more modern, perhaps even slightly nautical feel. Color choices are virtually limitless, ranging from subtle earth tones like warm beige and terracotta to bold, vibrant hues such as deep reds, greens, and blues.

Many manufacturers offer color palettes inspired by nature, historical architectural styles, and current design trends. The variety allows homeowners to precisely match their siding to their personal preferences and the architectural style of their home. Consider also the subtle differences in sheen; a matte finish offers a more rustic look, while a satin finish provides a more polished appearance.

Impact of Textures and Patterns

The texture and pattern of the siding significantly influence the overall appearance of a building. A smooth, flat surface creates a clean, contemporary look, while a textured surface, mimicking the look of wood grain or even stucco, adds depth and visual interest.

For instance, a home with deeply textured siding that replicates the look of cedar shakes will evoke a rustic, natural aesthetic. In contrast, a smooth, painted surface will give the home a more modern and minimalist feel. Some manufacturers offer siding with subtle patterns incorporated into the texture, creating a more visually complex and interesting facade.

These patterns can range from simple, repeating motifs to more intricate designs. The choice of texture and pattern should complement the overall architectural style and the homeowner’s personal taste.

Design Elements and Architectural Styles, Siding comparable to hardie board

Hardie Board’s popularity stems from its adaptability to various architectural styles. Its versatility in color, texture, and style allows it to seamlessly integrate into homes ranging from traditional Victorian to contemporary modern designs. For a traditional colonial home, the classic clapboard siding in a muted, historical color scheme would be an excellent choice.

The horizontal lines and subtle textures would enhance the home’s inherent charm. For a Craftsman-style home, a wider board and batten siding, perhaps with a slightly rougher texture, would complement the style’s emphasis on natural materials and handcrafted details.

A modern farmhouse might benefit from a smooth, painted fiber cement siding in a clean white or gray, accentuating the style’s minimalist aesthetic. The ability to mimic the appearance of other materials, like wood or stone, without the associated maintenance, is a significant factor in Hardie Board’s widespread appeal across diverse architectural styles.

Cost and Value Comparison

Choosing the right siding material involves a careful consideration of not only aesthetics but also long-term cost-effectiveness. This section compares the total cost of ownership for Hardie Board siding and several comparable alternatives, factoring in initial purchase, installation, and maintenance expenses over the material’s lifespan.

Understanding these costs helps homeowners make informed decisions aligned with their budget and long-term goals.

Cost Analysis of Hardie Board and Comparable Sidings

The following table provides a comparative cost analysis for a hypothetical 1,500 square foot house, illustrating the price differences between Hardie Board and alternative siding materials. Prices are estimates and can vary significantly based on location, labor costs, and specific product choices.

It’s crucial to obtain multiple quotes from reputable contractors for accurate pricing in your area.

| Siding Material | Material Cost (per sq ft) | Installation Cost (per sq ft) | Total Cost (per sq ft) |

|---|---|---|---|

| Hardie Board (Fiber Cement) | $3.00

|

$4.00

|

$7.00

|

| Vinyl Siding | $1.00

|

$2.00

|

$3.00

|

| Aluminum Siding | $2.00

|

$3.00

|

$5.00

|

| Wood Siding (Cedar) | $4.00

|

$5.00

|

$9.00

|

Influence of Material Lifespan and Energy Efficiency on Value

Material lifespan significantly impacts long-term costs. Hardie Board boasts a significantly longer lifespan (50+ years) compared to vinyl (20-30 years) or aluminum (30-40 years). This longevity translates to reduced replacement costs over the home’s lifetime.

Furthermore, Hardie Board’s superior insulation properties can contribute to lower energy bills, offering a long-term return on investment. For example, a homeowner might save $200-$500 annually on heating and cooling costs compared to a home with less efficient siding, adding up to substantial savings over several decades.

Return on Investment (ROI) of Siding Choices

The ROI of siding choices depends on several factors, including the initial investment, material lifespan, maintenance costs, and energy savings. While Hardie Board has a higher upfront cost, its longer lifespan and potential energy savings can result in a better ROI compared to less durable materials requiring more frequent repairs or replacements.

A real-life example could be comparing two homes: one sided with Hardie Board and another with vinyl. Over 30 years, the vinyl-sided home might require a complete siding replacement, incurring significant costs. The Hardie Board home, however, would likely require only minor maintenance, resulting in a higher overall ROI.

This calculation needs to consider individual circumstances, regional price variations, and energy consumption patterns.

Maintenance and Repair Procedures

Proper maintenance is crucial for extending the lifespan and preserving the aesthetic appeal of your Hardie Board or comparable siding. Regular cleaning and prompt attention to any damage will prevent minor issues from escalating into costly repairs. This section details the maintenance and repair procedures for these durable siding materials.

Cleaning and Maintenance of Hardie Board and Comparable Sidings

Regular cleaning helps prevent the accumulation of dirt, mildew, and algae, maintaining the siding’s appearance and protecting it from potential damage. For most siding types, a simple cleaning with a pressure washer (using a low-pressure setting to avoid damage) and a solution of mild detergent and water is sufficient.

For stubborn stains, a solution of bleach and water (always following manufacturer’s instructions) can be effective, but caution should be exercised to avoid damaging the siding’s finish. After cleaning, rinse thoroughly with clean water. Annual cleaning is recommended, with more frequent cleaning in areas with high humidity or heavy pollution.

Inspect the siding regularly for any signs of damage, such as cracks, dents, or loose boards.

Common Issues and Repair Methods for Hardie Board Siding

Hardie Board siding, while durable, is susceptible to certain types of damage. Cracks can occur due to impact or settling of the house. Repairing cracks involves cleaning the area, applying a compatible patching compound, and then painting to match the existing siding.

Dents can be repaired similarly, using a filler to level the surface. Loose boards typically indicate a problem with the underlying fastening system. These should be refastened securely, ensuring proper penetration and using appropriate fasteners. Water damage, often evidenced by discoloration or swelling, requires more extensive repair, possibly involving board replacement.

It’s crucial to address water damage promptly to prevent further deterioration.

Common Issues and Repair Methods for Fiber Cement Siding (Comparable to Hardie Board)

Fiber cement siding, while sharing similarities with Hardie Board, may have slightly different characteristics depending on the manufacturer. Common issues such as cracks and dents are addressed using similar methods to Hardie Board repair, involving patching compounds and careful repainting.

However, some fiber cement products might require specific patching compounds recommended by the manufacturer. Loose boards necessitate refastening, similar to Hardie Board. Water damage is also a concern and should be addressed swiftly to avoid structural issues.

Always refer to the manufacturer’s instructions for specific repair guidelines.

Long-Term Maintenance Requirements and Costs

The long-term maintenance costs for Hardie Board and comparable siding are generally low compared to other siding materials. Regular cleaning, as described above, is the primary maintenance requirement. Occasional repairs, as needed, are the main cost factor. The frequency and cost of repairs depend on several factors, including the climate, the quality of installation, and the level of exposure to the elements.

For example, a home in a coastal area might require more frequent cleaning and repairs due to salt spray and harsh weather conditions compared to a home in a milder climate. While unexpected repairs can occur, the overall long-term cost is significantly lower than materials requiring more frequent painting or replacement.

For instance, a typical annual maintenance cost might be around $100-$200 for cleaning supplies and minor repairs, while major repairs, which are infrequent, could range from $500-$1500 depending on the extent of damage. These are estimates, and actual costs can vary based on individual circumstances.

Environmental Impact and Sustainability

Choosing sustainable siding materials is crucial for minimizing the environmental footprint of a home. This section compares the environmental impact of Hardie Board and comparable alternatives, considering manufacturing processes, material sourcing, disposal methods, and overall lifecycle assessments. We’ll explore the sustainability features of each material, including recycled content and recyclability, to provide a comprehensive understanding of their environmental profiles.

Manufacturing and Disposal of Hardie Board and Alternatives

Hardie Board, a fiber cement product, has an environmental impact stemming from the energy consumption in its manufacturing process, which involves cement production (a significant CO2 emitter), and the use of other raw materials. Disposal often involves landfill space, although some regions offer recycling programs for construction debris.

Alternative siding materials, such as vinyl, wood, and aluminum, also have varying environmental impacts. Vinyl production uses fossil fuels and releases greenhouse gases. Wood siding, while a renewable resource, requires harvesting and transportation, and its longevity can be affected by pests and decay.

Aluminum siding, although recyclable, requires significant energy for its initial production. The environmental impact of each material is influenced by factors like transportation distances, manufacturing processes, and the specific composition of the product. Life cycle assessments, which consider the environmental impact across the entire lifespan of a product, are increasingly important in evaluating these materials.

Sustainability Features of Siding Materials

The sustainability of siding materials can be assessed by considering their recycled content, recyclability at end-of-life, and the use of renewable or sustainable resources in their manufacturing. Some manufacturers offer Hardie Board with a portion of recycled content, although the percentage varies.

Vinyl siding generally has a low percentage of recycled content, and its recyclability is limited. Wood siding, being a natural product, is often considered more sustainable than other options, particularly if sourced from responsibly managed forests. However, the use of wood preservatives and treatments can introduce additional environmental concerns.

Aluminum siding boasts high recyclability rates, but the energy-intensive manufacturing process remains a significant factor. A life cycle assessment helps to balance these considerations and provide a more holistic view of sustainability.

Life Cycle Assessment of Siding Materials

A life cycle assessment (LCA) provides a comprehensive analysis of a product’s environmental impact across its entire life cycle, from raw material extraction to manufacturing, transportation, use, and disposal. While precise LCA data varies depending on specific product formulations and regional factors, general comparisons can be made.

Studies have shown that the environmental impact of Hardie Board is influenced by the cement content, with efforts focused on reducing the embodied carbon in the manufacturing process. Vinyl siding typically has a higher carbon footprint due to its reliance on fossil fuels.

Wood siding’s impact depends heavily on sourcing and treatment, while aluminum siding’s environmental burden is largely concentrated in the initial manufacturing stage. These LCAs help inform informed decisions by quantifying and comparing the environmental impacts of different siding options.

Comparing LCAs from reputable sources is crucial for accurate assessments.

Conclusion

Ultimately, selecting siding comparable to Hardie Board requires careful consideration of numerous factors. This guide has provided a detailed comparison of various materials, highlighting their strengths and weaknesses across material composition, installation, aesthetics, cost, maintenance, and environmental impact. By weighing these factors against your specific needs and preferences, you can confidently choose a siding option that enhances your home’s beauty, durability, and value for years to come.

Remember to consult with professionals for personalized advice and accurate cost estimations.